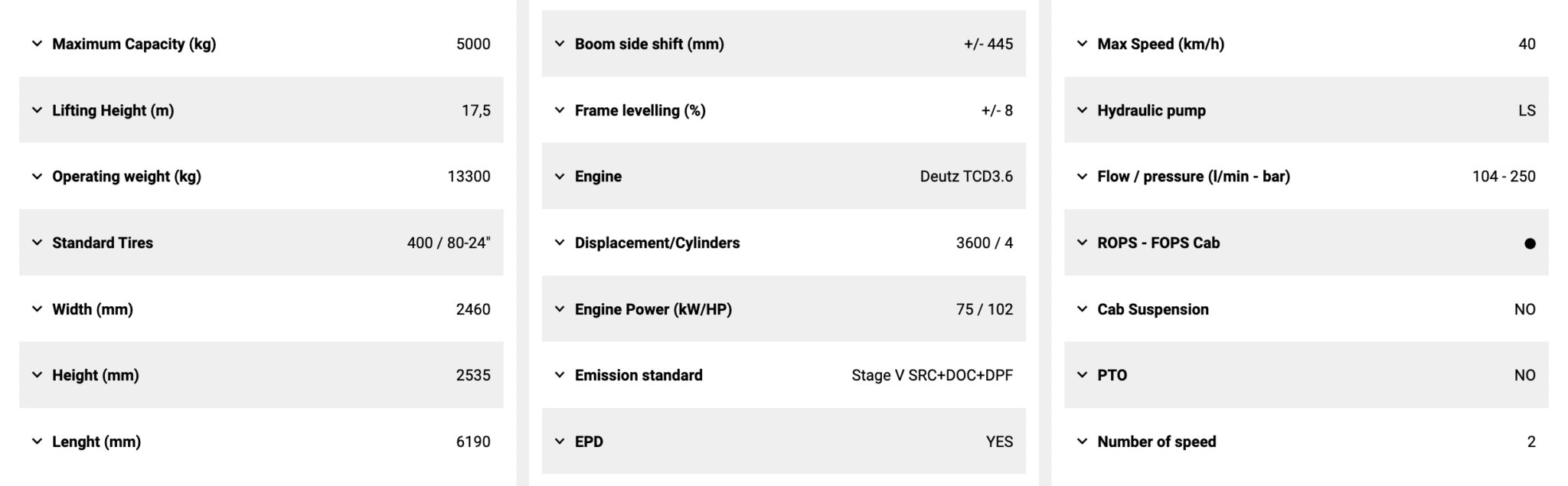

Merlo Stabilized Telehandler (P50.18 Plus)

The Panoramic 50.18 PLUS was developed to offer the highest level of technology in terms of efficiency, performance and versatility of use to serve the most demanding operators.

PERFORMANCE

Everything at your fingertips

Exclusive precision:

Guarantees maximum movement precision, thanks to the hydrostatic transmission, which ensures millimetric variations in the machine’s movements and load’s positioning.

Compact and lightweight:

The Merlo telescopic handlers are compact and lightweight to reduce manoeuvring space and impact on the ground. These features guarantee safety, manoeuvrability, productivity and lower consumption.

Visibility:

Merlo telescopic handlers are designed to offer the best visibility on the market, ensuring faster and safer operations.

STABILISERS

Chassis levelling:

The tilt correction system, integrated into the chassis, is available as standard on this model. It allows the operator to offset the ground slopes to work in total safety. On sloping terrain the operator can correct the lateral inclination by 8% on each side, reaching 24% with the combined action of the stabilisers. This allows the telescopic boom to be moved out perpendicularly to work in conditions of maximum safety.

Boom side-shift:

This model is equipped with the exclusive boom side-shift, a system integrated into the telescopic boom that allows the load to be positioned without further manoeuvring, consequently saving time, avoiding stress and improving the machine’s productivity.

The system allows for a boom side-shift up to 870 mm.

COMFORT

The best workplace

Quiet and comfortable:

The new cab, of generous dimensions, is mounted on Silent Blocks, which drastically reduce vibrations, guaranteeing maximum comfort and maximum visibility for the operator.

Quick accessories changeover:

The Tac-Lock system for hydraulic clamping of the attachments further improves operating comfort.

Protection of the handled load:

The boom suspension system (BSS) is available as an option, which protects the load during transfer and maintains a high level of driving comfort on rough terrain.

SAFETY

Not just feelings

Record-breaking safety:

The Merlo integrated safety system controls the operating parameters in real time, allowing the operator to work in peace.

Certified cabs / Certified protection:

The Merlo cab is FOPS – Level II – and ROPS certified, to guarantee a high level of safety for the operator.

Exclusive safety:

The exclusive new generation Merlo Dynamic Load Control (CDC) system automatically detects the type of attachment used, the machine’s geometric configuration, the “boom extension and angle” and the handled load.

All information is displayed on the LCD screen, allowing the operator to use the telescopic handler simply and safely.

EFFICIENCY

Simpler and smarter

Simple and precise operations:

The entire range is equipped with hydrostatic transmission, which makes the work phases simpler and more precise. Moreover, the dry disc brakes limit the absorption of energy, thereby reducing the machine’s fuel consumption.

Reduced consumption:

The exclusive Eco Power Drive (EPD) technology automatically controls and adjusts the engine revolutions based on operating conditions. As a result, the engine speed is disconnected from the accelerator pedal. This technology achieves a reduction in fuel consumption of up to 18%.

The cabin is designed to guarantee our customers a record level of comfort. With its 1010 m, it is the widest in the category, but acoustic and thermal comfort have also been studied in detail. In addition, the low-frequency hydropneumatic shock absorber system drastically reduces vibrations inside the passenger compartment and in the driver’s seat.

Air conditioning:

The air conditioning system is completely new and was developed according to automotive standards, halving the warm-up and cool-down times, in order to guarantee the optimum temperature in all conditions.

The Merlo cab can reach an optimal internal temperature even in extreme climatic conditions. The intake port is located on the side of the cab away from potential sources of dust and dirt to maximize filter longevity. Inside there are 8 vents, three of which are dedicated to defrost the windscreen, for optimal climatic comfort.

ROPS/FOPS:

The Merlo cab is FOPS – Level II – and ROPS certified. This ensures a high level of safety for the operator.

Pressurization:

The latest generation Merlo cab integrates a pressurization system compliant with the ISO 10263-3 standard.

Visibility:

Merlo telehandlers are known all over the world for their extraordinary visibility, thanks to the large glass surface of 4.3 m2 and the exclusive design of the roof.

180° Opening Door:

Exclusive door that opens 180° for easy access and independent upper window: air exchange, visibility and direct contact with those who work outside are guaranteed without compromise.

The Merlo designers have adopted technologically advanced diesel engines, advanced hydrostatic transmissions and axles equipped with dry disc brakes, which contribute to reducing power absorption. Diesel engine/transmission management is electronic to optimise performance and minimise energy consumption.

Deutz 115 HP engine:

This model is equipped with a 115 HP (85 kW) four-cylinder Deutz Stage Tier IV engine. The engine complies with anti-pollution regulations with the DOC (Diesel Oxidation Catalyst) and SCR (Selective Catalysis Reduction).

40 Km/h Speed:

This model offers a maximum speed of 40 km/h.

Load sensing:

The variable displacement pump with the Load Sensing hydraulic distributor guarantees higher performance, more efficiency and increased productivity while simultaneously limiting consumption and component wear.

The transmission system is managed in a way that guarantees a high static starting torque, smooth progression and an optimisation of cycle times and consumption.

Merlo designs and produces its own axles internally, which are thus made and tailored to each application, enhancing performance and safety for each model.

Portal axles:

The portal axles are made with a crown wheel and pinion gear reducer and ensure ample ground clearance. The kinematic structure reduces noise and pitch during braking and acceleration, improving cornering and transferring under load.

Three steering modes:

Merlo telescopic handlers offer three steering modes: only the front wheels, pivot steering and crab steering.

This exclusive solution adopted on the axles guarantees the maximum steering angle to perform manoeuvres in tight spaces.

Four-wheel drive:

The driving wheels, which are always engaged, are synonymous with maximum traction in all operating conditions.

Braking:

The integral servo-assisted braking system acts on the four wheels for maximum safety in every working context. Parking brake: activates automatically when the engine is switched off or can be engaged manually from the cab.

The PANORAMIC range’s stabilisers are simply structured to optimise fast and safe installation. The exclusive design of the stabilisers, developed to offer a high structural resistance, guarantees their limited encumbrance during the operating phases, always staying within the machine’s silhouette and limiting the visual encumbrances for the transfer phases.

The independent control allows for the single operation of each stabiliser, providing easier positioning on the ground.

Moreover, the shape of the support foot guarantees excellent anchorage to the ground, even in the case of soft or steep soils.

The Merlo designers have devised a sturdy, compact and lightweight telescopic boom, today a benchmark for design, load capacity and speed when carrying out work. The chosen steel is of the structural type with welds along the neutral bending axis, offering a rectilinear boom in any extension or loading condition.

Boom 17,5 m:

The boom consists of four sections: the maximum lift height is 17.5 metres for unrivalled versatility.

The components – including the boom extension cylinder, the hydraulic pipes and the electric cables – are housed within a cartridge structure inserted in the boom. This exclusive solution considerably increases the longevity of the components and makes the external shape clean and snag free, allowing for rapid maintenance operations.

Tac-Lock:

The attachments are easily replaceable, thanks to the exclusive Tac-Lock system for the hydraulic locking of the attachments, thereby improving operating comfort.

Hydraulic and electrical connections:

Hydraulic and electrical connections are available at the end of the boom, allowing for the movements of the various usable attachments to be operated directly from the cab.

Related products

Contact us

- +357 25 755 866

- +357 25 725 940

- [email protected]

- Falea & Koutsoventi Corner, Ayios Athanasios Industrial, 4011 Limassol, Cyprus

Services

About us

Demetriades Group is located in Limassol, Cyprus and has its roots dating back to 1995 when Vasos Demetriades founded the first company Demetriades Handling, as an importer and supplier of used forklifts.